NEWS

Welcome to our news section, where we keep you up to date with the latest in innovation and trends. Explore our recent product launches, the most advanced technologies and the solutions that are revolutionising the industry. Here you'll find what you need to stay one step ahead - don't miss any updates!

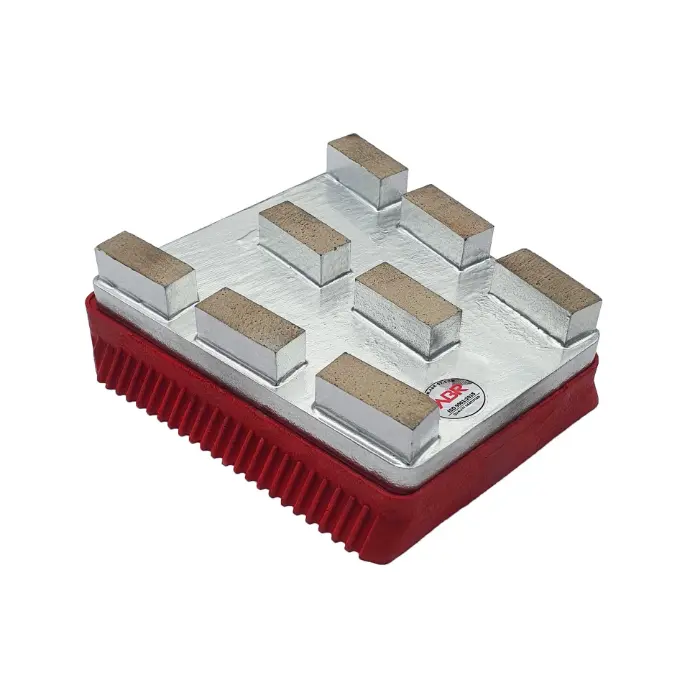

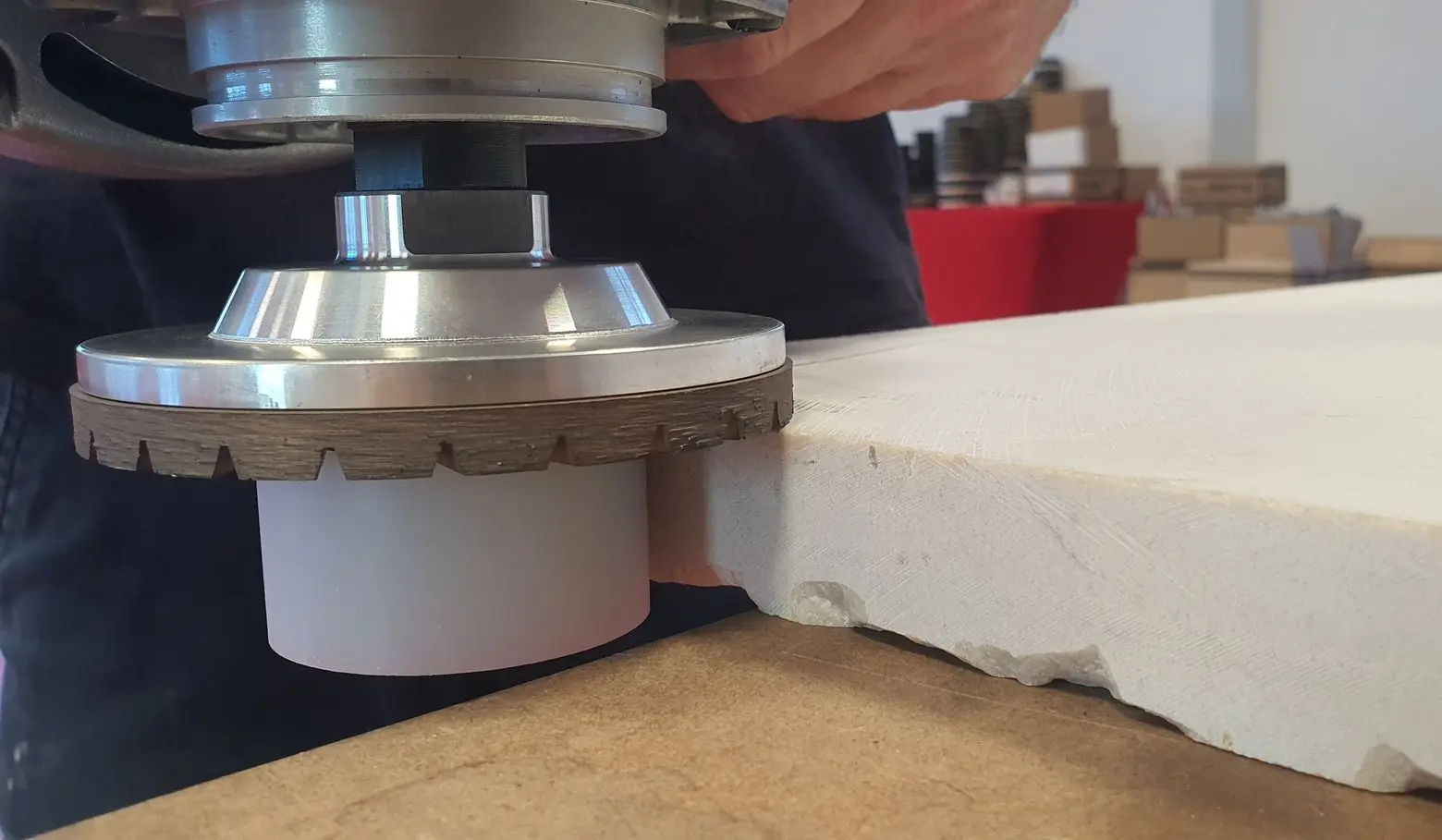

Quickly bevels all materials

Removes lettering and reinforcing mesh without scratching the surface

Possibility of use with light machines

It only takes one disc to achieve an exceptional platinum shine in a very short time.

With this simple system we reduce the number of passes to achieve the desired shine and cleanliness, reducing time and costs, as well as 100% of chemical product expenditure.

Non-slip, traffic-safe and accident-free floors, both wet and dry.

Only water is needed, no chemicals are necessary. Avoids chemical odours and stains.

It is not necessary to invest in new machinery to start using this new system of floor polishing and maintenance.

Thanks to the ULTRABOND technology you can achieve the desired gloss level on floors, stairs, worktops, tables and stone shelves, even a MIRROR GLOSS.

Technologies

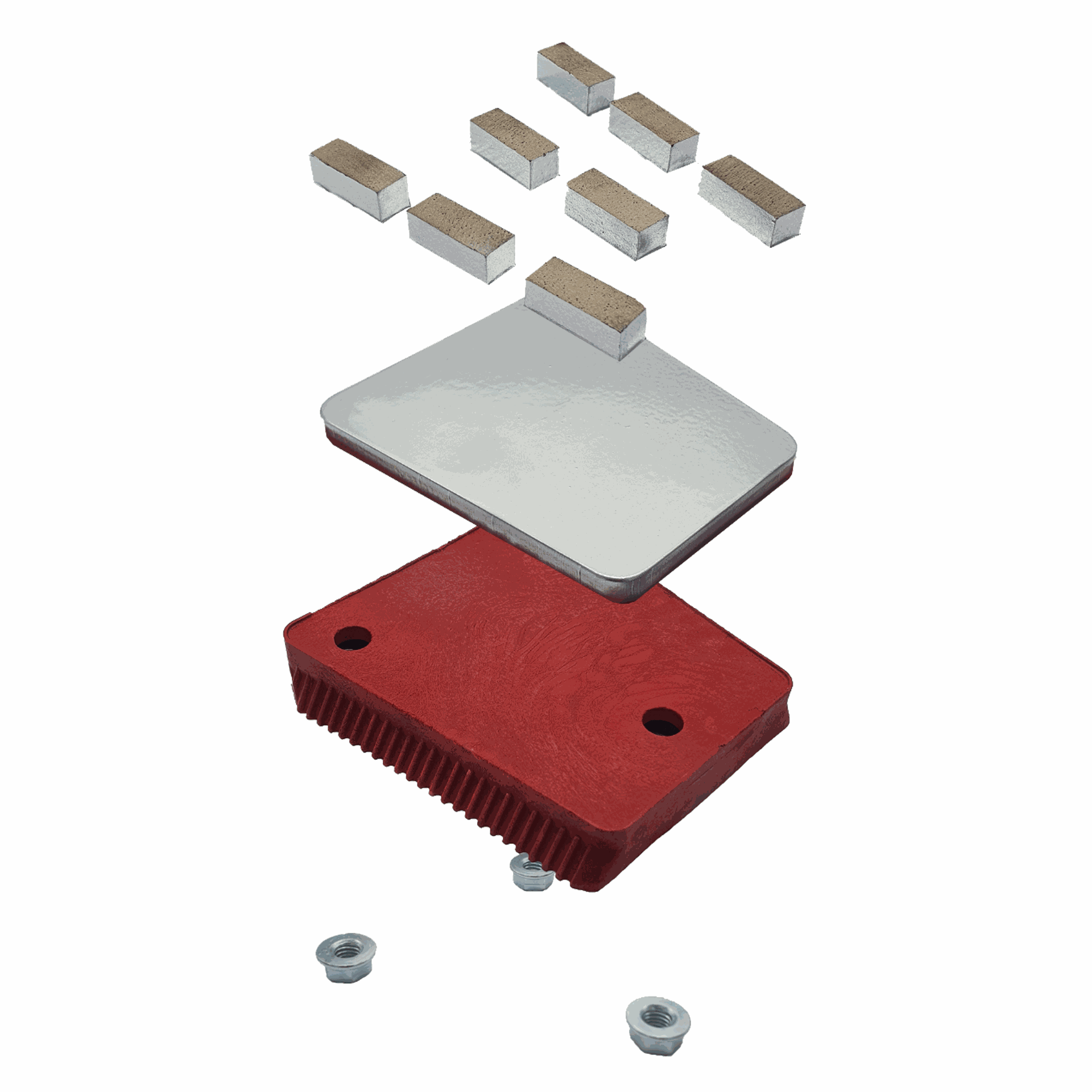

ULTRABOND PLATINUM includes different technologies to offer maximum performance and quality for your use.

Enables the exact dispersion and positioning of the diamond grains on the outside of a net-like support with structure.

A controlled and homogeneous dispersion of the diamond makes this technology the perfect combination for Resinoid Diamond Abrasives.